Remain Ahead of Deterioration: Necessary Upkeep Tips for Undercarriage Parts

Wiki Article

Make The Most Of Efficiency With Durable Undercarriage Components

In the world of heavy machinery and devices, the function of undercarriage components is extremely important in guaranteeing ideal efficiency and longevity. The effectiveness and efficiency of these elements can dramatically influence the general operation of machinery, making the selection of sturdy undercarriage components an important decision for supervisors and operators alike. By discovering the elaborate partnership between sturdiness and efficiency in undercarriage parts, a much deeper understanding of the subject emerges, losing light on the essential factors that drive functional success. As we navigate via the complexities of undercarriage maintenance, component, and long life choice, a detailed expedition awaits to unveil the crucial methods for attaining peak performance in durable applications.Advantages of Using Resilient Undercarriage Parts

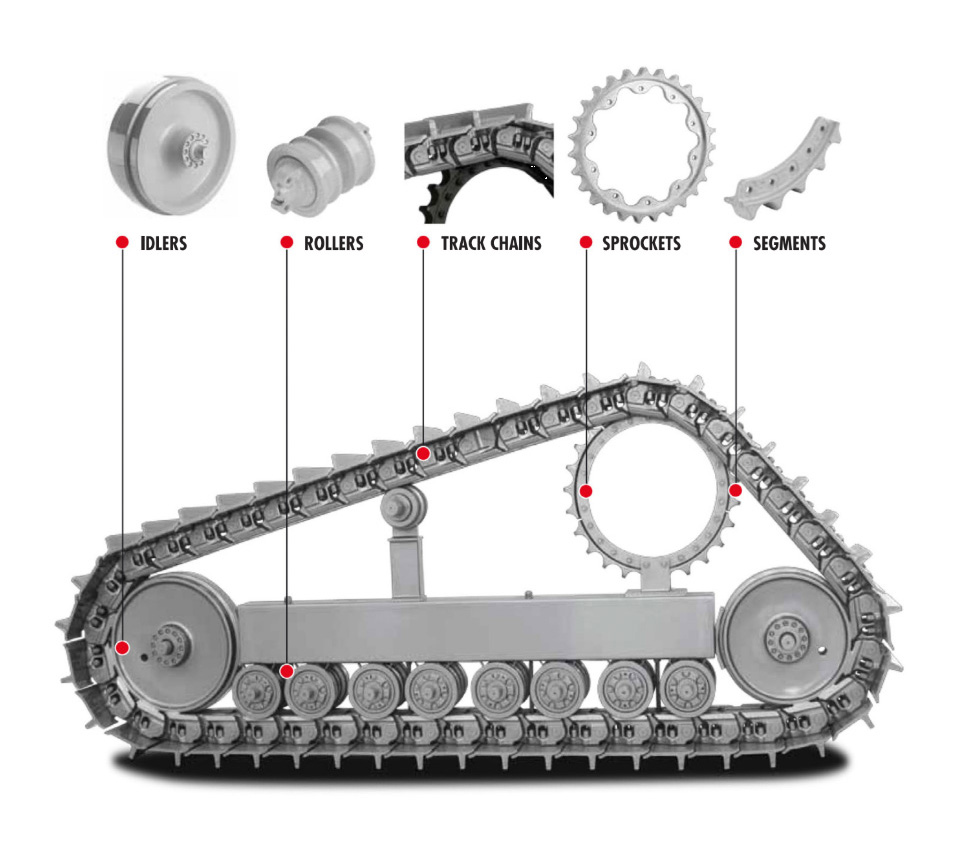

Making use of long lasting undercarriage components not just enhances the long life of hefty machinery but likewise minimizes maintenance expenses substantially. By spending in high-grade undercarriage elements, such as tracks, gears, rollers, and idlers, tools drivers can experience enhanced uptime and improved overall efficiency.

Furthermore, the longevity of hefty machinery is straight connected to the quality of its undercarriage components. Sturdy elements can endure the rigors of demanding applications, making sure that the devices remains functional for extensive periods. Therefore, operators can prevent costly downtime and maintenance expenditures, inevitably making the most of the roi for their equipment.

Aspects Affecting Undercarriage Toughness

The longevity of undercarriage components in heavy machinery is affected by numerous critical elements that directly effect efficiency and durability. High-quality materials, such as hard steel, are necessary for enduring the severe conditions and heavy loads that undercarriage parts are subjected to - undercarriage parts.Additionally, ecological elements can have a substantial influence on the durability of undercarriage components. Exposure to unpleasant materials, extreme temperature levels, and extreme working conditions can speed up wear and tear on undercarriage elements. For that reason, choosing undercarriage parts that are specifically made to stand up to these environmental obstacles is crucial for guaranteeing toughness.

In addition, the design and engineering of undercarriage components have a straight impact on their durability. Parts that are created to disperse lots equally, reduce friction, and reduce stress and anxiety focus are much more most likely to have a much longer life-span - undercarriage parts. By considering these vital aspects, tools operators can make the most of the longevity and performance of their undercarriage this post elements

Upkeep Tips for Lengthening Undercarriage Life

Applying normal upkeep regimens is important for extending the lifespan of undercarriage elements in hefty machinery. In addition, guarantee that the undercarriage is effectively lubed according to manufacturer standards to decrease rubbing and avoid early wear.Another important maintenance pointer is to keep the undercarriage tidy from dirt, rocks, and debris. Buildup in the undercarriage can increase wear and rust, bring about expensive repair work. Cleaning the undercarriage after operation in extreme conditions is suggested to avoid these problems.

Lastly, monitoring and recording maintenance tasks can assist in producing an aggressive upkeep timetable. Maintaining in-depth records of substitutes, examinations, and repairs can give valuable insights right into the undercarriage's problem and performance in time, assisting in predicting and protecting against possible failures. By adhering to these maintenance suggestions diligently, drivers can considerably raise the resilience and efficiency of undercarriage components in heavy machinery.

Choosing the Right Undercarriage Elements

Choosing suitable undercarriage elements is important for making best use of the efficiency and longevity of hefty equipment. When it comes to picking the ideal undercarriage elements, there are several factors to consider.Furthermore, thinking about the quality and credibility of the producer is important. Selecting trusted brands understood for creating long lasting and high-performance undercarriage parts can dramatically influence the general performance and long life of the equipment. Moreover, making sure that the elements work with the equipment design and properly set up is crucial for ideal performance. By carefully choosing the appropriate undercarriage components, useful content devices proprietors can boost productivity, minimize downtime, and expand the lifespan of their heavy equipment.

Study: Enhanced Performance With Sturdy Components

Including durable undercarriage components has actually demonstrated considerable her explanation improvements in machinery efficiency. One instance study included a construction business that updated its excavator's undercarriage components to a lot more sturdy options.In one more circumstances, a mining operation replaced the undercarriage components of its excavator with top quality, long lasting alternatives. This button led to an exceptional renovation in the bulldozer's ability to move and total performance. The machine might browse difficult surfaces much more successfully, causing enhanced operational performance and decreased gas usage.

Additionally, a logging business spent in resilient undercarriage components for its forestry devices. The upgraded elements exhibited extended lifespan and boosted resistance to abrasion from rough surface. The firm experienced lowered maintenance expenses and better equipment uptime, ultimately increasing its bottom line. These study emphasize the tangible benefits of using durable undercarriage parts in optimizing equipment efficiency and durability.

Verdict

In verdict, using resilient undercarriage components can dramatically boost efficiency and longevity of hefty equipment. Elements such as proper upkeep and selecting the right components play an important role in making best use of undercarriage durability. By applying these approaches, services can minimize downtime, boost efficiency, and ultimately minimize functional expenses. Study have actually revealed that purchasing sturdy undercarriage components can result in improved total performance and performance in different industries.The efficiency and efficiency of these elements can dramatically influence the general procedure of equipment, making the selection of resilient undercarriage components a crucial decision for supervisors and drivers alike.Including durable undercarriage parts has actually shown substantial enhancements in machinery performance. These situation researches underscore the concrete advantages of making use of durable undercarriage parts in optimizing machinery performance and durability.

In verdict, utilizing resilient undercarriage components can considerably enhance efficiency and longevity of heavy machinery (undercarriage parts). Situation research studies have actually revealed that spending in durable undercarriage parts can lead to enhanced general efficiency and performance in numerous industries

Report this wiki page